We Make

a Difference

We Make

a Difference

Our Strategy

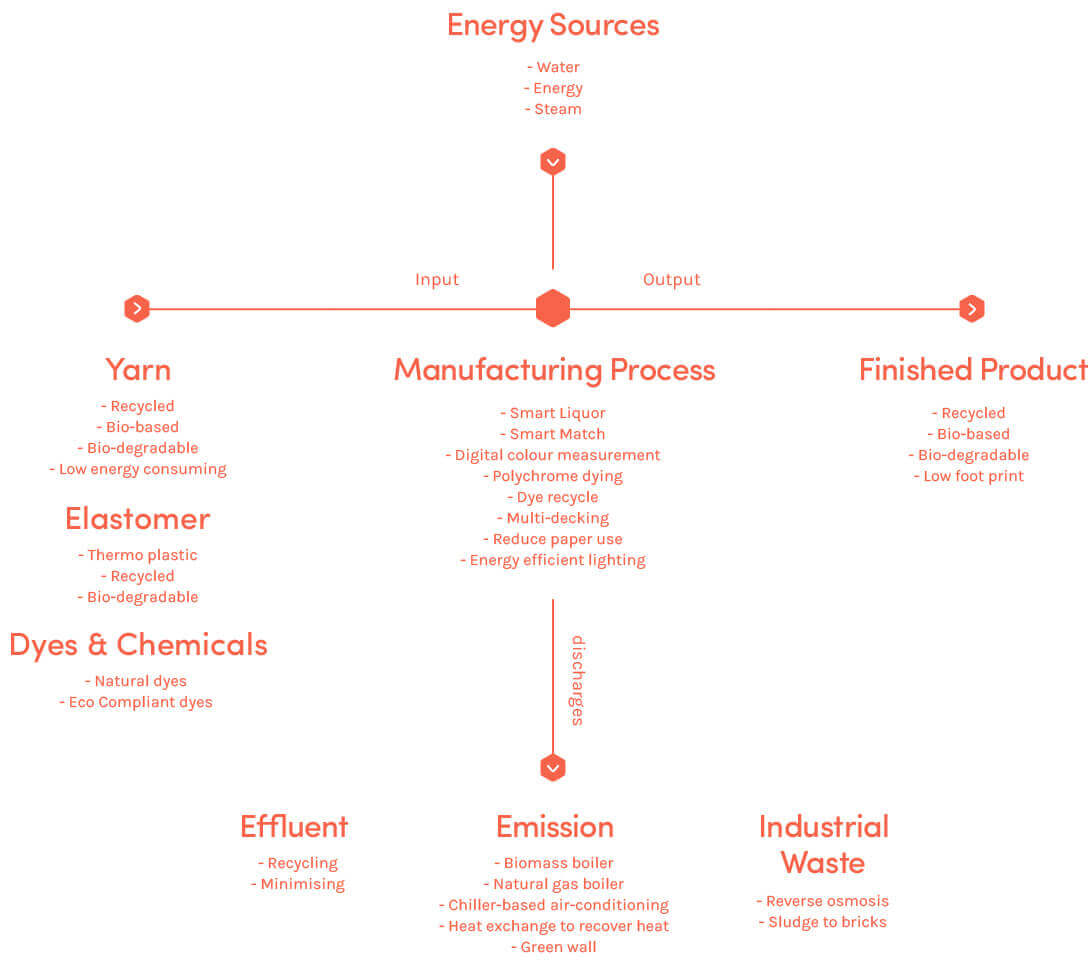

At Stretchline, we base our eco-ethos on the “6R’s principle”. We care about the source and the lifecycle of our products as well as how we manufacture them. This means we are always experimenting with new materials, processes and technologies which have a lower environmental impact.

-

Rethink

-

Refuse

-

Reduce

-

Repair

-

Recycle

-

Reuse

Sustainable Yarns

Sustainable yarns are the way forward for a greener planet. From recycled plastic bottles and industrial waste, to high tech plant based yarns, we work with the world’s leading raw material suppliers within this field.

Eco-compliant dyestuff & chemicals

We work with Bluesign approved suppliers who share the same values in sustainable manufacturing practices that we do. We also have a unique range of plant-based natural dyes which substantially reduce the impact on the environment.

Water Saving Initiatives

By using state of the art digital colour matching tools, we have reduced both energy and water usage whilst maximising our ‘right first time’ colour matching accuracy. With online measurements of dye bath exhaustion, our dye house water consumption has reduced substantially since 2015.

Vertical Gardens

In a ground-breaking initiative to reduce the impact of emissions, our local team has planted a ‘green wall’ at our facility in China. By using a specialised spider plant proven to reduce air pollution, we have made our site more environmentally friendly whilst improving the eco system.

Our 360 Sustainability

approach

- Rolling out Solar power across all sites

- Elimination of Coal

- Reduced water consumption

- Recycling Sludge to Bricks programme

- Natural Light increase across all plants

- Rolling out LED lights across all sites (censored lights to reduce light wastage)